Band saw

• Long hair must be tied back.

• Safety goggles must be worn to prevent small pieces of objects from flying into your eyes.

• Never leave the machine operating when it is unattended.

• Use two hands at all times.

• Don’t have too many people near the machine.

• Always rest the material you are cutting on the table – do not hold it above the table.

• Keep hands away from the blade.

• Closed in shoes must be worn when using the machine.

• Material smaller than 3cm should not be cut using this machine.

Belt sander/disc sander

• Long hair must be tied back.

• Safety goggles must be worn to prevent small pieces of objects from flying into your eyes.

• Never leave the machine operating when it is unattended.

• Use two hands at all times.

• Closed in shoes must be worn when using the machine

• Material smaller than 3cm should not be sanded using this machine.

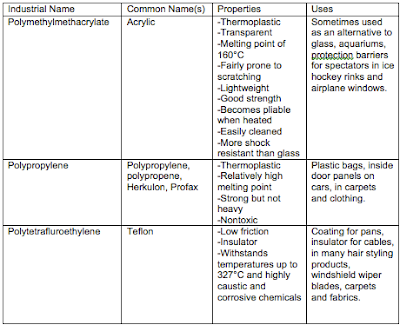

2. The material you are using for your desk tidy is called Polymethylmethacrylate (ACRYLIC). It has specific properties and uses. Choose 2 other common polymers and in table form give their industrial name, common name, properties and uses.

3. Extrusion, injection moulding, compression moulding, vacuum forming and laminating are examples of common manufacturing processes used with polymers (Plastics). Choose one process and with the use of diagrams and bullet points outline the process.

Vacuum Forming:

-Firstly, a mould is made using a material such as wood of cardboard. The edges are made at an angle that will make it easy to remove the plastic after it is formed.

-This mould is then placed in the vacuum former.

-A sheet of plastic is clamped above the mould.

-A heater gradually melts the plastic so it becomes pliable. After a few minutes it is ready for forming.

-The heater is then turned off and a lever is used to lift the plastic until it is in position.

-The vacuum is the turned on, which pumps the air out from beneath the plastic sheet, causing it to form around the mould.

-After the sheet has cooled down and become solid again, the vacuum is turned off and the sheet and mould are removed from the vacuum. The sheet would have taken the shape of the mould.

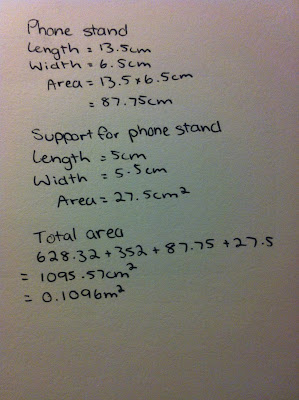

4. Extension Work - Using processes acquired from your maths lessons, calculate the amount of acrylic sheet that your FINAL desk tidy represents. Show all calculations; answer needs to be in square metres.

Therefore, the amount of acrylic used in my desk tidy is 0.1096 square metres.

No comments:

Post a Comment